Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

How can we help you?

The organic waste in landfills is covered and compressed by heavy equipment to create an anaerobic condition, a biological decomposition process that does not involve oxygen and breaks down organic matter. HOFFMAN & LAMSON blowers extract the byproducts from the anaerobic digestion process. Vacuum is applied to a perforated piping system to control and withdraw the resulting gas. Primarily comprised of 50%-70% methane (CH4) and 25%-50% carbon dioxide (CO2), this gas is both hazardous and potentially useful. If the gas remains in the landfill, then explosions can occur. If leaked into the atmosphere, it contributes to smog as a hazardous gas known as volatile organic compounds (VOC).

Landfills in the United States must estimate the quantity of non-methane organic compounds emitted to the atmosphere. If these landfill emissions exceed 50 tons per year, then they are required to contain and clean the gas to remove the non-methane organic compounds. Usually, the methane gas is burned off or flared, which requires a vacuum producer and compressor to remove gas from the ground and feed into the flare.

HOFFMAN & LAMSON blowers are the ideal solution for landfill gas extraction because they are engineered to handle the pressures and flows typical for landfill gas flare system demands.

If economically feasible, the gas is cleaned to pipeline quality as “renewable natural gas” or “biomethane”. The gas can be added to the gas pipeline grid and mixed with natural gas. Additionally, the biomethane gas can be used to heat water or air or heat part of an industrial process. If compressed, biomethane can power internal combustion or fuel cell vehicles.

Hoffman & Lamson provides durable and cost-effective blowers/exhausters for landfill gas applications. These landfill gas solutions are reliable, safe, require limited maintenance, and provide the following:

The team at Hoffman & Lamson was given the challenge of engineering a system that would clean and convert the gas for use in the CHP plant.

HOFFMAN & LAMSON blowers/exhausters for landfill gas are flexible and allow variable flow capabilities with or without a variable frequency drive (VFD), which is critical for maintaining proper flow for combustion. Moreover, our blowers/exhausters are efficient and contribute to energy and cost-savings with our custom-engineered configurations.

Additionally, our blowers/exhausters are virtually maintenance-free because of no wearing parts; although routine and preventative maintenance are recommended and performed onsite with nominal operational downtime.

The landfill gas process begins with decomposition and common applications include landfill gas extraction to flare, and landfill gas to energy.

Organic matter is decomposed when organic waste in landfills is covered and compressed by heavy equipment. There are four stages of decomposition:

The methane gas created by the anaerobic process in a waste landfill must be vented to prevent explosions. This gas is usually flared off to be safely disposed of.

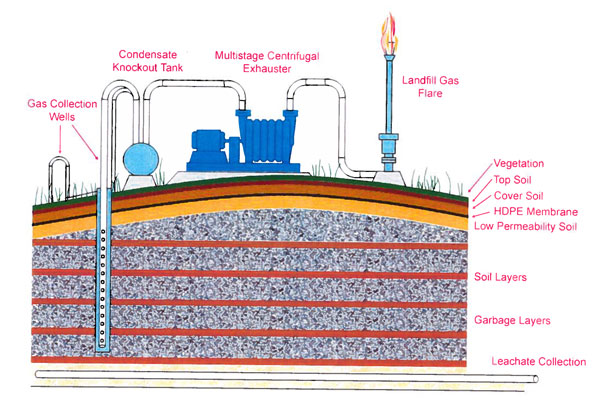

Areas are carefully prepared for new landfills with a base of clay, sand, and membrane designed to prevent leachate from reaching the groundwater. A layer of garbage is added, compacted mechanically, and topped with a layer of soil.

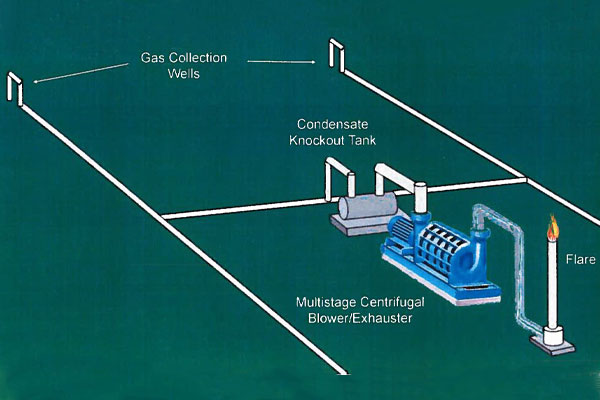

Another layer of garbage and more soil is added, and so on until the landfill section is deemed full. The area is then topped with special low permeability soil, an HDPE membrane, more soil, and vegetation cover. Holes are bored and piping collects the potentially hazardous methane gas. The quantity of vent pipes is determined based on many factors including the rate of decomposition, climate, thickness, the number of layers, and more. A multistage centrifugal blower/exhauster forces the gas mixture, mostly methane gas and carbon dioxide, to leave the landfill and send it to the landfill gas vent flare.

This process can use one or multiple multistage centrifugal blowers/exhausters. A single blower/exhauster could draw from twenty or fifty vent pipes; however, the vent pipes must be engineered to draw an even vacuum. Multiple blowers/exhausters can address this potential issue.

The methane gas created by the anaerobic process in a waste landfill must be vented to prevent explosions. This gas can be valuable and is often saved.

If economically feasible, the gas is cleaned to pipeline quality as “renewable natural gas” or “biomethane”. The gas can be added to the gas pipeline grid and mixed with natural gas. Additionally, the biomethane gas can be used to heat water or air or heat part of an industrial process. If compressed, biomethane can power internal combustion or fuel cell vehicles.

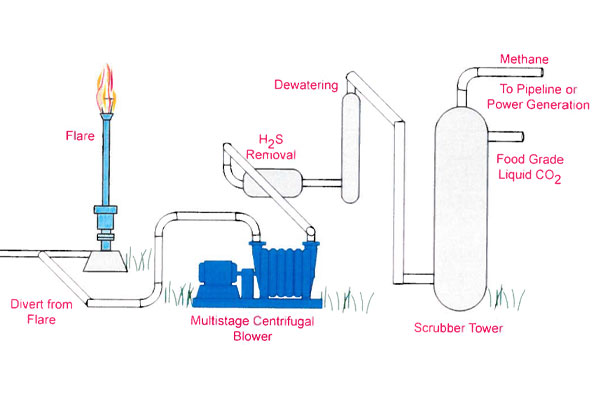

After the landfill gas blower/exhauster passes the methane and carbon dioxide mixture, it is diverted to a second blower/exhauster, which goes to hydrogen sulfide removal, a dyer and scrubber tower, or to clean the gas. At this time, food-grade CO2 can be separated from the methane. Siloxane trace contaminants are also removed and hinders combustion. An aftercooler may be required to cool the volatile methane gas after compression. The cleaned methane gas moves to a storage vessel where it can be used in the process or added to the natural gas grid.

Equipment is tested before reaching the customer or end-user. Thus, ensuring top quality and avoiding operational downtime. Therefore, upholding Hoffman & Lamson’s strong reputation as the global leader of engineered solutions and producing premier quality products efficiently and economically. There are over 100,000 HOFFMAN & LAMSON multistage centrifugal blowers/exhausters in operation worldwide.

Equipment is tested before reaching the customer or end-user. Thus, ensuring top quality and avoiding operational downtime. Therefore, upholding Hoffman & Lamson’s strong reputation as the global leader of engineered solutions and producing premier quality products efficiently and economically. There are over 100,000 HOFFMAN & LAMSON multistage centrifugal blowers/exhausters in operation worldwide.

ABOUT Hoffman™ and Lamson™

Hoffman™ and Lamson™ brands of centrifugal blowers and exhausters are among the many compressed air and gas technologies manufactured by Gardner Denver Inc.

Part of the Nash Division, they are American originals. Hoffman™ and Lamson™ brands have been setting industry standards for excellence, reliability, and customer satisfaction for over 100 years. Lamson, established in 1880, and Hoffman, in 1905, are brands customers know and continue to trust.