Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

How can we help you?

Wastewater aeration is a vital component in wastewater treatment, enhancing the breakdown of organic pollutants and improving overall water quality. Wastewater aeration is critical to biological treatment systems including aerobic activated sludge systems, Sequencing Batch Reactors (SBR), nitrification-denitrification in a single basin, and Membrane Bioreactors (MBR).

Treatment plants inject pressurized air into a liquor of sludge and wastewater. Promoting the growth of microorganisms that consume organic matter and supply the air for diffused aeration systems.

Hoffman and Lamson specialize in cutting edge aeration solutions tailored to meet the harsh demands of wastewater treatment facilities. As leaders in aeration in wastewater treatment, we are committed to delivering reliable, energy-efficient solutions.

In this phase, biological processes, like aerobic treatment, decompose organic compounds, and pollutants in the wastewater. Chemical oxidation is used to remove persistent organic pollutants, bacteria, and microbial pathogens.

Typically, the secondary phase removes chemicals and toxic compounds. It is not uncommon to repeat this phase several times or apply tertiary treatment to the water.

A well-designed aeration system directly impacts the level of wastewater treatment achieved. The key to rapid, economic, safe, and effective wastewater treatment is an aeration system that evenly distributes oxygen supply.

Aeration is an activated sludge process. It pumps air into a tank, promoting microbial growth in wastewater. Bacteria that forms the activated sludge, after settling in a separate settling tank, recirculates back to the aeration basin. Recirculating back to the aeration basin increases the decomposition rate.

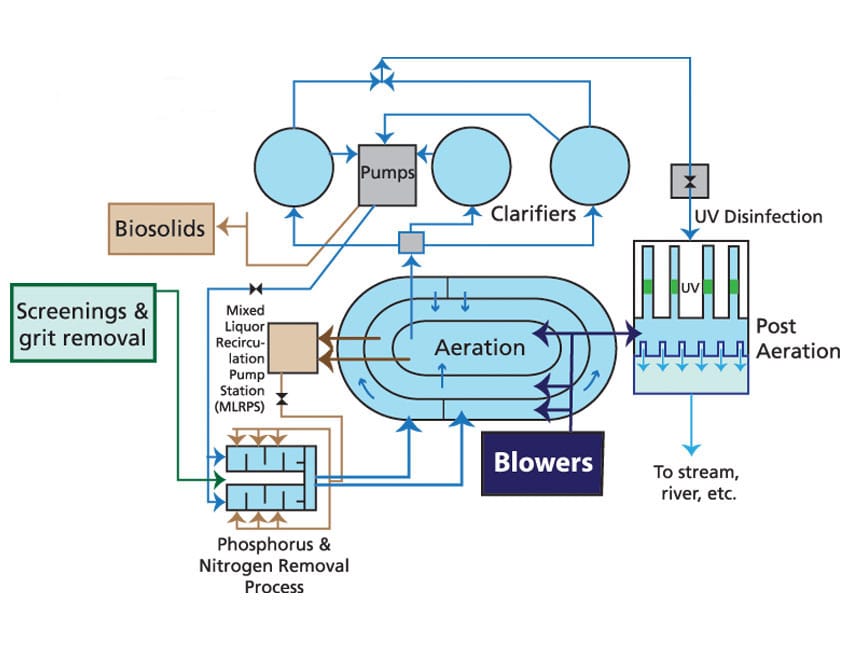

High volumes of wastewater will require more complex systems compared to simple batch processes used by smaller-scale facilities. The plant design below shows how a system impacts the level of wastewater treatment achieved.

The aeration phase removes organic matter, fine particles, and potentially toxic and harmful chemicals from the influent that enters the system. Read on to learn more about wastewater treatment aeration locations.

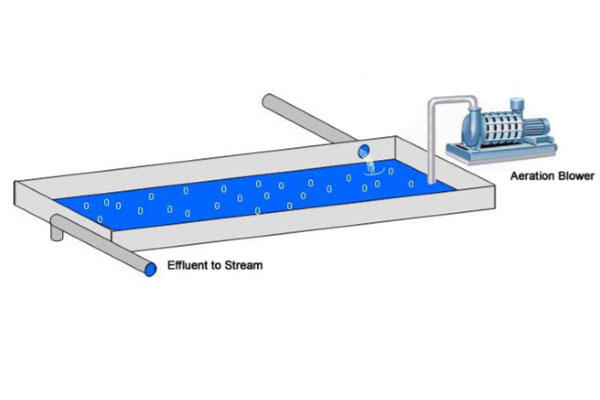

An aerated lagoon or aerated basin is a holding treatment pond that supplies artificial aeration. Artificial aeration promotes the biological oxidation of wastewater.

Aeration basins are large, open earthen lagoons or ponds. The large surface areas involved cause more drastic temperature variations than those found in aerobic digesters. Thus, causing variations in sludge retention times. If solids return to the aeration basin process, then there is no difference between an aeration basin and the activated sludge process.

Aerobic digesters are tanks constructed of concrete and are rectangular. This is so multiple tanks can share common walls. Large tanks would have fewer diffusers where most plants have at least two digesters. The aerobic digestion process can be continuous or batch.

The objective of suspension mixed lagoons is to convert the soluble, biodegradable organics in the influent into biomass that can settle as sludge. Usually, the effluent is then put in a second pond where the sludge can settle. The effluent is then removed from the top with a low chemical oxygen demand (COD), while the sludge accumulates on the floor and undergoes anaerobic stabilization.

Suspension mixed lagoons convert the soluble, biodegradable organics in the influent into biomass that can settle as sludge. The effluent goes to a second pond where the sludge can settle. Then, it is removed from the top with a low chemical oxygen demand (COD), while the sludge accumulates on the floor and undergoes anaerobic stabilization.

Two functions are provided in a surface aerated system:

(1) Transfer air into the basins to facilitate biological oxidation reactions.

(2) They provide the mixing required for dispersing the air and for contacting the reactants (that is, oxygen, wastewater, and microbes).

The floating surface aerators deliver oxygen for aeration. However, surface aerators do not provide mixing that is equivalent to what is achieved in activated sludge systems.

Submerged diffused air is a form of a diffuser grid inside a lagoon. The two main types of submerged diffused aeration systems for lagoon applications are floating and submerged lateral. Both systems utilize fine or medium bubble diffusers to provide aeration and mixing of the process water. The diffusers can be suspended slightly above the lagoon floor or may rest on the bottom.

Channels that distribute wastewater to the primary sedimentation tanks are aerated to keep the solids in suspension, and independent of the water flow rate. The amount of air required ranges and mixed liquor turns to activated sludge settling tanks that are aerated.

Requirements for effluent demand high dissolved oxygen levels. The regulation intends to ensure that low dissolved oxygen level effluent does not mix with a receiving stream.

Submerged diffused air is essentially a form of a diffuser grid inside a lagoon. The two main types of submerged diffused aeration systems for lagoon applications are floating lateral and submerged lateral. Both of these systems utilize fine or medium bubble diffusers to provide aeration and mixing of the process water. The diffusers can be suspended slightly above the lagoon floor or may rest on the bottom.

In large wastewater plants, channels that distribute wastewater to the primary sedimentation tanks are aerated to keep the solids in suspension, and independent of the water flow rate. The amount of air required ranges from 2-5 cfm per linear foot of channel (0.2-0.5 m3/linear meter/minute). Frequently, the mixed liquor to activated sludge settling tanks are aerated.

Recent requirements for effluent demand high dissolved oxygen levels (4 to 8 MG/L). The intent of the regulation is to ensure that low dissolved oxygen level effluent is not mixed with a receiving stream.

One method is cascade aeration, where the effluent is aerated by the turbulence of a series of waterfalls. However, the temperature of the water greatly affects the water’s ability to absorb oxygen.

One method is cascade aeration, where the effluent is aerated by the turbulence of a series of waterfalls. However, the temperature of the water greatly affects the water’s ability to absorb oxygen.

Diffuser aeration is used in larger treatment plants. Diffusers are dependent on the oxygen transfer rate required by the effluent.

Discover the Hoffman & Lamson Advantage

At Hoffman & Lamson, we are not just another blower manufacturer. We are wastewater experts, dedicated to revolutionizing the industry with innovative solutions tailored to your unique needs. With a deep understanding of wastewater aeration processes, we go beyond mere product offerings to provide comprehensive support and expertise that sets us apart from the competition.

Our team of seasoned professionals boasts decades of collective experience in the wastewater sector. We leverage this expertise to engineer cutting-edge aeration solutions that optimize efficiency, minimize energy consumption, and maximize the effectiveness of your treatment processes.

What sets us apart is not just our products, but our approach. We don't just sell blowers; we offer customized solutions backed by unparalleled expertise in wastewater aeration. From initial consultation to ongoing support, we work closely with you to understand your specific challenges and tailor our offerings to address them effectively.

With a focus on continuous improvement and innovation, we stay ahead of the curve in an ever-evolving industry. Our commitment to research and development ensures that you benefit from the latest advancements in wastewater treatment technology and aeration, giving you a competitive edge in efficiency, performance, and sustainability.

When you choose Hoffman & Lamson for your wastewater aeration needs, you're not just getting a product; you're gaining a trusted partner dedicated to your success. Experience the difference firsthand and discover why we are the preferred choice for leading wastewater treatment facilities worldwide.

Contact us today to learn more about how our wastewater experts can elevate your wastewater treatment process with our expertise-driven solutions, including blowers for wastewater, wastewater blowers, and aeration blowers for wastewater.

ABOUT Hoffman™ and Lamson™

Hoffman™ and Lamson™ brands of centrifugal blowers and exhausters are among the many compressed air and gas technologies manufactured by Gardner Denver Inc.

Part of the Nash Division, they are American originals. Hoffman™ and Lamson™ brands have been setting industry standards for excellence, reliability, and customer satisfaction for over 100 years. Lamson, established in 1880, and Hoffman, in 1905, are brands customers know and continue to trust.