Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

How can we help you?

For more than a century, Hoffman™ and Lamson™ have been recognized as global leaders of centrifugal blowers and exhauster systems. Our extensive catalog offers a powerful selection of centrifugal blowers tailored to meet diverse industrial needs. Explore our multistage, high-speed turbo, fabricated, and regenerative blower systems that are manufactured with cutting-edge technology and engineered to maximize productivity and minimize energy costs.

Hoffman™ and Lamson™ engineers leverage the latest technology to design efficient and durable centrifugal blowers suitable for various industrial applications. Whether you require uniform pressure, pulse-free flow, or oil-free operation, our centrifugals are customizable to your specific application requirements.

What is a centrifugal blower? A centrifugal blower is a type of fan or air-moving device designed to increase the velocity of air or gases and deliver them to a specific location. The fundamental principle behind a centrifugal blower is to convert rotational energy into kinetic energy, resulting in a high-pressure airflow.

How does a centrifugal blower work? The core component of a centrifugal blower is the impeller, which is a rotating disk with blades or vanes attached. Air or gas enters the blower through an inlet at the center of the impeller. As the impeller spins, the centrifugal force pushes the air or gas towards the outer edges of the impeller, increasing its velocity. When the impeller spins, it creates a centrifugal force that throws air or gas outwards. The high-velocity air or gas is then expelled through a discharge port or outlet and results in a high-pressure airflow that can be directed to the desired location.

Experience the REVOLUTIONPLUS series of high-speed turbo blowers, offering increased reliability with minimal maintenance. Our turbo blowers deliver energy savings of up to 40% and are designed for extreme environments.

High speed blowers provide increased reliability with low maintenance requirements. They are factory pre-wired and tested in an ergonomically designed sound enclosure for plug-and-play operation.

To learn how our high-speed turbo blowers set a new standard for blower design, performance, and efficiency, click the link.

Explore Our High-Speed Turbo Blowers

Hoffman and Lamson multistage centrifugal blowers are custom engineered using one or many stages of impellers to move air or gas. These blowers are the ideal solution for processes requiring uniform pressure, pulse-free flow, and oil-free operation.

Multistage centrifugal blowers are flexible and allow variable flow capabilities with or without a variable frequency drive (VFD). Choosing the most efficient blower will contribute to energy and cost savings due to inlet throttling, custom-engineered configurations, and no wearing parts. No wearing parts mean our blowers are virtually maintenance-free. Although routine and preventative maintenance are recommended and performed on-site with nominal operational downtime.

No wearing parts mean our blowers are virtually maintenance-free. Although routine and preventative maintenance are recommended and performed on-site with nominal operational downtime.

Our fabricated centrifugal blowers and exhausters provide the advantages of multistage centrifugal blowers but at the most economical price point. With the ability to provide airflow up to 1,400 CFM (2,000 m3/h), and vacuum up to 10.5 inHg (350 mbar).

Fabricated blowers are designed for less demanding applications that do not require high vacuum performance.

Explore Our Fabricated Centrifugal Blowers

Regenerative blowers are designed to provide continuous and pulse-free air with the versatility to perform in numerous air applications.

Our regenerative blowers are available as belt-driven blowers, direct drive, overhung, and even VFD variable speed configurations.

Explore Our Regenerative Blowers

HOFFMAN & LAMSON certified remanufactured blowers are built with the same high-quality standards as new blowers. They are thoroughly tested, and backed by the same certified warranty as a new unit. Remanufactured blowers offer an excellent, cost-effective alternative to new machines. They are ideal for short-term projects, spares, or permanent installations.

Hoffman and Lamson centrifugal blowers are durable, reliable and efficient. Our products are recognized across industries for their high-quality design. With a wide selection of centrifugal blower systems, backed by more than 100 years of engineering expertise, you can trust Hoffman and Lamson to provide a solution that compliments and improves your application needs.

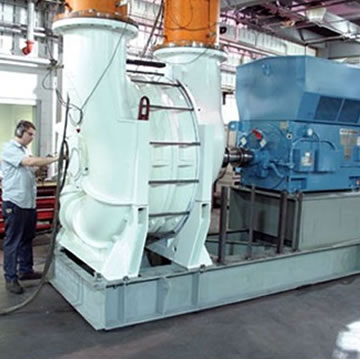

Hoffman and Lamson have placed customers at the heart of our operating philosophy for more than a century. Our experience, engineering expertise, and reputation deliver groundbreaking innovation for centrifugal blower solutions. Our equipment is tested before reaching the customer or end-user. This ensures top quality and reduces the risk of issues or downtime.

Our industrial centrifugal blowers are recognized around the world as the best solutions for water & wastewater treatment.

Hoffman and Lamson centrifugal blowers are valued for their robustness and ability to handle varying operating conditions, making them versatile tools in many industrial settings. Blowers in our portfolio are commonly used in water and wastewater treatment plants and across many other general industrial applications. Browse our industry and application cards and brochures below to learn more.

With several hundred thousand installations worldwide, Hoffman and Lamson brings quality innovation and experience to water and wastewater treatment solutions. Whether you’re treating water for a clean water supply or treating wastewater, Hoffman and Lamson offers the widest and most comprehensive range of blowers/exhausters and engineered package solutions of any manufacturer.

Since 75% or more of the total life cycle costs of operating aeration equipment is energy, energy efficiency is our number one priority. The footprint of the REVOLUTIONPLUS is significantly smaller than traditional blowers - reducing energy consumption and the carbon footprint. Our turbo blowers deliver up to 45% energy savings, provide increased reliability with little to no maintenance, and comes factory prewired and tested in an ergonomically designed sound enclosure for plug-and-play operation.

ABOUT Hoffman™ and Lamson™

Hoffman™ and Lamson™ brands of centrifugal blowers and exhausters are among the many compressed air and gas technologies manufactured by Gardner Denver Inc.

Part of the Nash Division, they are American originals. Hoffman™ and Lamson™ brands have been setting industry standards for excellence, reliability, and customer satisfaction for over 100 years. Lamson, established in 1880, and Hoffman, in 1905, are brands customers know and continue to trust.