Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

How can we help you?

When used with municipal wastewater, membrane bioreactor processes can produce effluent of sufficient quality to be discharged to waterways or used for irrigation. Advantages of membrane bioreactors over conventional wastewater treatment processes include a small footprint and the retrofit and upgrade of old wastewater treatment plants.

Hoffman & Lamson is a global leader of engineered solutions and produces premier quality products efficiently and economically.

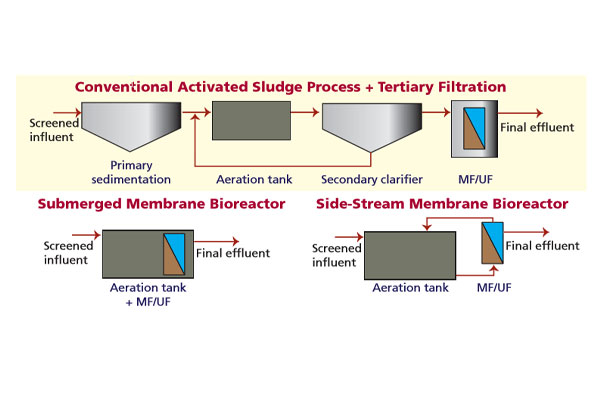

Membrane bioreactors were designed with the separation device located external to the reactor (side-stream MBR) and relied on high transmembrane pressure (TMP) to maintain filtration. The introduction of a submerged membrane bioreactor system, with the membrane directly immersed in the bioreactor, quickly led to it becoming the preferred configuration, especially for typical North American wastewater treatment.

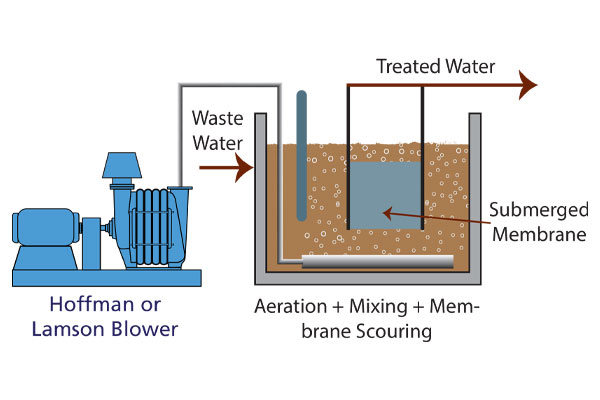

The submerged membrane bioreactor relies on coarse bubble aeration to produce mixing and limit fouling. The energy demand of the submerged system is much less than that of the side-stream systems. Whereas, submerged systems operate at a lower flux, demanding more membrane area. In submerged configurations, aeration is considered as one of the major parameters in process performance, both hydraulic and biological. Aeration maintains solids in suspension, scours the membrane surface, and provides oxygen to the biomass, leading to better biodegradability and cell synthesis.

Two membrane bioreactor configurations exist: internal/submerged, where the membranes are immersed in and integral to the biological reactor. The second configuration is external/side-stream, where membranes are a separate unit process requiring an intermediate pumping step.

Internal/Submerged

The filtration element is installed in either the main bioreactor vessel or in a separate tank. The membranes can be a flat sheet or tubular or a combination of both. These can incorporate an online backwash system, which reduces membrane surface fouling by pumping membrane permeate back through the membrane.

Additional aeration is required to provide air scour to reduce fouling. Where the membranes are installed in the main reactor, membrane modules are removed from the vessel and transferred to an offline cleaning tank.

External/Side-StreamThe filtration elements are installed externally to the reactor. The biomass can be pumped directly through several membrane modules and back to the bioreactor. Alternatively, the biomass can be pumped to a bank of modules, from which a second pump circulates the biomass through the modules in series. Cleaning and soaking of the membranes can be undertaken in place with the use of an installed cleaning tank, pump, and pipework. Despite the more favorable energy usage of submerged membranes, there continues to be a market for the sidestream configuration, particularly in industrial applications. For ease of maintenance, the side-stream configuration can be installed on a lower level in a plant building and membrane replacement can be undertaken without specialized lifting equipment.

Equipment is tested before reaching the customer or end-user. Thus, ensuring top quality and avoids unforeseeable issues or operational downtime. Therefore, upholding Hoffman & Lamson’s strong reputation as the global leader of engineered solutions and producing premier quality products efficiently and economically. There are over 100,000 HOFFMAN & LAMSON multistage centrifugal blowers and exhausters in operation worldwide.

ABOUT Hoffman™ and Lamson™

Hoffman™ and Lamson™ brands of centrifugal blowers and exhausters are among the many compressed air and gas technologies manufactured by Gardner Denver Inc.

Part of the Nash Division, they are American originals. Hoffman™ and Lamson™ brands have been setting industry standards for excellence, reliability, and customer satisfaction for over 100 years. Lamson, established in 1880, and Hoffman, in 1905, are brands customers know and continue to trust.