Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

How can we help you?

Hoffman & Lamson high-speed turbo blowers combine an advanced blower management system with a significantly smaller footprint than traditional blowers to set a new standard for design, efficiency, and performance. HOFFMAN's REVOLUTIONPLUS Series offers various turbo blower models with power inputs ranging from 10 to 700 horsepower, making them an ideal choice for a wide range of applications.

Our customers count on us to help them reduce their carbon footprint. Our REVOLUTIONPLUS models are designed with performance and operational benefits in mind. Each unit is engineered with dynamic balancing impellers and fitted with a compact and durable high-speed motor coupled with our patented air foil bearing technology. Combining these with other innovative design elements, Hoffman's high-speed blowers provide increased reliability, require minimal maintenance, and deliver energy savings of up to 40%. HOFFMAN turbo blowers are factory prewired and tested in an ergonomic sound enclosure for plug-and-play operation.

Seventy percent of aeration equipment life cycle operating costs are dedicated to energy usage and energy efficiency. Hoffman & Lamson make it a top priority to help our customers reduce their carbon footprint and energy consumption while improving operational efficiency.

HOFFMAN's REVOLUTIONPLUS high-speed turbo blowers have set new industry standards with an effective design to improve the operator's use and blower performance. Each model is fitted with a compact and efficient high-speed motor that has a life span up to 4x greater than standard motors and requires minimal maintenance. The series is manufactured with impellers made from Class III Anodized Aluminum for durability and then combined with our latest multi-foil air bearing patented design and coating technology.

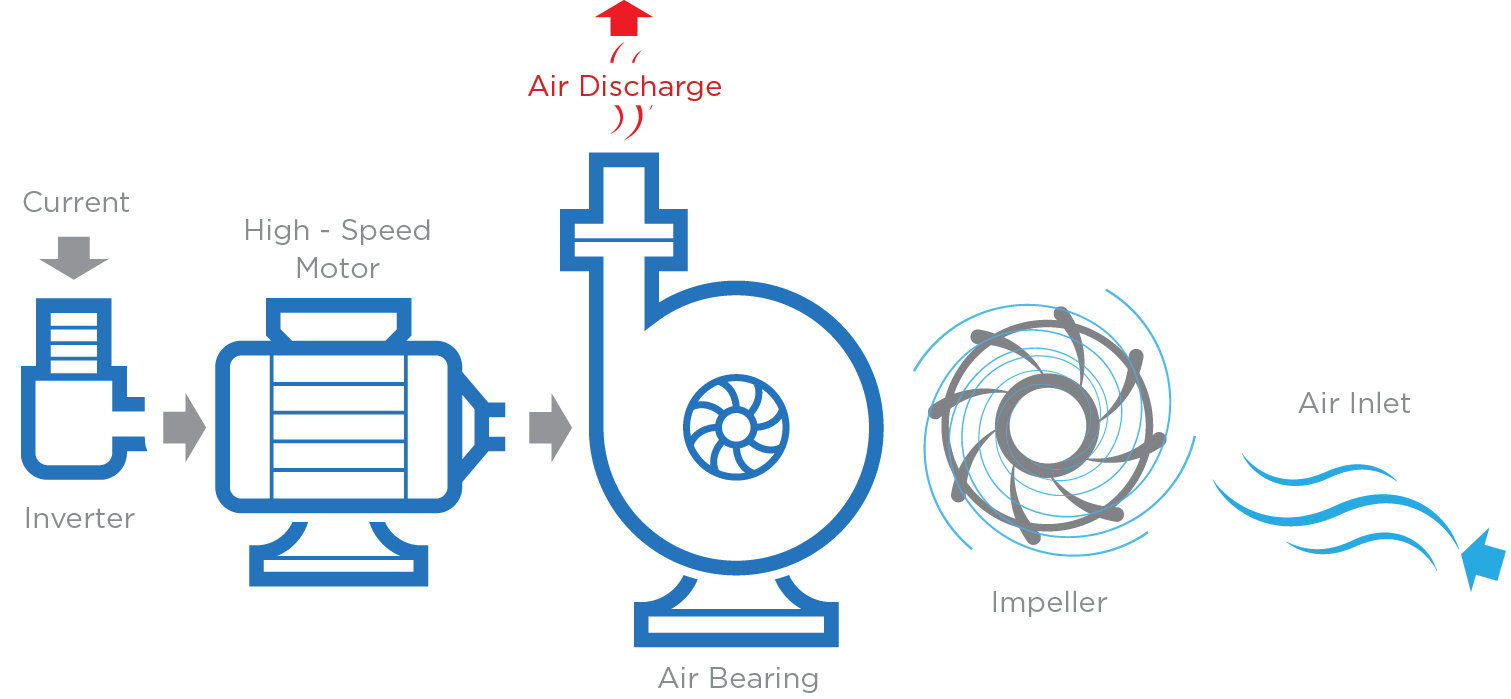

HOFFMAN’s REVOLUTIONPLUS turbo blowers consist of a compression unit equipped with a blow-off valve that releases air, protecting the unit during start/stop, while an inverter controls the rotating speed of the blower’s high-speed motor. Housed in a robust, sound-insulated enclosure, the REVOLUTIONPLUS series features a Programmable Logic Controller (PLC); allowing operators to actively monitor, control, and adjust the speed to meet changing process demands and operating conditions.

The high-speed motors within a REVOLUTIONPLUS turbo blower provide a much higher operational velocity, output, and performance than traditional induction motors. All HOFFMAN high-speed turbo blowers are fitted with a VSD (variable speed drive) as standard. The VSD adjusts the motor’s operating speed to meet operational requirements. These features allow operators to tailor the performance to meet oxygen demand, further increasing the levels of efficiency that they can provide.

High-EfficiencyProvides energy savings of up to 40% and a significantly reduced carbon footprint. |

Low Noise LevelConstructed to mitigate noise pollution <85 dBA sound rating. |

Simple MaintenanceNo belt, no gears, no oil. Schedule preventative maintenance inspection every 3 years - excluding air filters. |

OperationThe blower can operate separately from the controller, up to 100 feet maximum. |

Easy InstallationCompact design requires no special foundation support due to leveling feet. |

Complete PackageAccess panels to electronics and air-end equipped with gasket material to protect from damage caused by exterior dirt and debris. |

HOFFMAN's REVOLUTIONPLUS Series of high-speed turbo blowers stands out amongst other manufacturers because of our advanced design and patented air bearing design and coating technology. Impellers are available in various designs including cast, fabricated, and moulded. Impellers are critical to the performance of any high-speed blower, so Hoffman utilizes single block machined aluminum across the range with pitch and blade variations for different pressure requirements. Our multi-foil air bearing design allows for tighter tolerances which increases the stability in a wider range of rotational speeds. The superior construction of the bearing material, including heat treatment and a Teflon coating, acts as a suspension that improves the damping capability by 30% compared to the single foil designs seen on other high-speed blowers available in the market.

Visit Our High-Speed Turbo Blower Technology Page to Learn More

ABOUT Hoffman™ and Lamson™

Hoffman™ and Lamson™ brands of centrifugal blowers and exhausters are among the many compressed air and gas technologies manufactured by Gardner Denver Inc.

Part of the Nash Division, they are American originals. Hoffman™ and Lamson™ brands have been setting industry standards for excellence, reliability, and customer satisfaction for over 100 years. Lamson, established in 1880, and Hoffman, in 1905, are brands customers know and continue to trust.